- USD

- EUR

- GBP

FREE SHIPPING in UK for orders over £75!

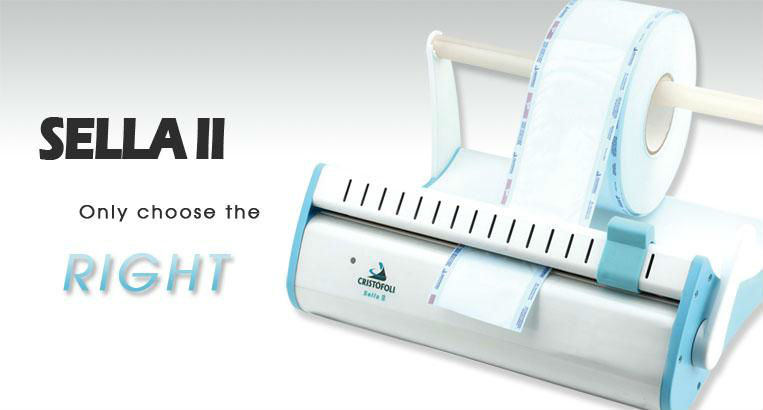

Dental Sealing Machine SEAL Autoclave Sterilization Beep-alert Equipment

Dental Sealing Machine SEAL Autoclave Sterilization Beep-alert for Energy Saving Design

Note:It weighted over 8.0kg after package,charged standard and expedited shipping service.

Please understand that economic shipping is cost saving but spend much time to delivery the item to most countries,to improve customs experience,additional shipping fee is charged for standard and expedited shipping only but NO economical shipping.

PLEASE read shipping cost before bidding.

Specifications

1) Beep-alert (for heating Status);

2) Energy saving design;

3) Comes with integrated cutting and roll support;

Sella II is intended for sealing envelopes for steam sterilization. Follow strictly the instructions and orientations from the manufacturer of your packages regarding their appropriate usage, cautions, conservation and storage.

WARNING! Since the sealer works at high temperatures, be careful not to accidentally touch its hot areas. The blades are very sharp and, in order to avoid accidents, caution is required when handling them.

a) Instruction

- Connect the power cord to the power connector which is on the back side of the sealer, check if the voltage of your equipment matches the voltage of the local electrical network.

- Switch the sealer on by using the power switch on its back side and adjust the sealing temperature through the temperature selector on its right side according to the thickness of the material to be sealed. When the green LED goes off (after around 2 minutes) the sealer will be ready to be used.

- Place the roll on the holder. The beginning of the roll shall be inserted through the back side, between the pressure bar and the sealing bar always with the paper side down (resistance’s side) and the plastic side up (directly under the upper pressure bar). Pull the sealer arm towards the operator and press it down softly until it is locked. Exaggerated pressure may break the sealer arm and this kind of damage is not covered by the warranty. The sealing time (around 4 seconds) must be manually controlled by the user.Note: If the sealing temperature is too low or too high the sealing might be inefficient (the envelopes may be stuck to the sealing area when they are pulled or be visibly badly-sealed). To correct this, adjust the timer properly. Once adjusted it is not necessary to perform any other adjustment to continue sealing.

- To cut the packages, still with the arm locked, slide the blade from one side to the other, raise the sealer arm and remove the envelopes. Note: If the blade knob is pulled slowly the paper may crease and the cutting will not be adequate. To make it more precise, pull the blade knob quickly. If necessary, slide the cutting blade more than once.

b) Notes

- Keep the sealing platform always clean. The accumulation of waste on the sealing area will reduce the life cycle of the resistance and the insulating material. For an effective cleaning, wait for the sealing area to cool down and use a cloth slightly moistened with alcohol.

- If the insulating material lower tape is worn the sealer may go faulty and the resistance may be damaged. Being so, every time the resistance is replaced, please also check the insulating material tape and replace it if it is worn.

- If it is necessary to replace the resistance or the fuse, use only those which have the same specifications as the genuine parts’.

- While packing the instruments protect the ones which have cutting and piercing tips with cotton or gauze to avoid the packages rupture.

- Place the sealed envelopes with instruments into the autoclave. Check the instructions from the manufacturer of your autoclave regarding the arrangement of the packages and the sterilization cycle.

- Unplug the power cord when servicing or cleaning the equipment.

c) Technical parameters

Sella II | |||

Power input |

AC 110/220 V 50/60 Hz |

Pre-heating time |

2 – 3 minutes |

Power output |

100 W |

Heat preservation |

Yes |

Seal width |

12 mm |

Dimensions (W*L*H) |

46*36*17 CM |

Seal length |

30 cm |

Gross weight |

7.5 KG |

Please Note: images and descriptions may not accurately represent the product. You are encouraged to confirm that the manufacturer item code above matches the product you seek. If you are uncertain or have questions, please contact with us thru ebay message for additional information. Thank you.

On 17-Jul-14 at 23:24:44 AEST, seller added the following information:

On 22-Nov-16 at 03:54:10 AEDST, seller added the following information:

On 22-Nov-16 at 03:54:14 AEDST, seller added the following information: